A Traceable Line In The Fashion Supply Chain

BUILDING A BETTER BRAND FROM THE GROUND UP.

Our plan has always been to show and tell. It’s not enough to say that we want to be different; we must show that our social and sustainable values are meaningful through action and then find ways to communicate what we’re doing to our customers.

The whole process needs to be built on transparency, trust, and soon, total traceability.

That’s why we often share videos of what happens in our factories through social media. We’re proud of our making process, the artisans we work with. We want people to see behind-the-scenes, to give an insight into all the different phases and elements that go into the shoes and clothes that we create in Spain and Portugal in our own factory, and partner factories.

PEOPLE AND CRAFT HAVE ALWAYS BEEN AT THE HEART OF MIIISTA.

We don’t just want to be known for providing the bare minimum, we want to set the standard. Build careers, maintain craft and manufacturing in Europe, show that we’re not another business that’s solely driven by profit. Be a better fashion brand.

What we don’t often share is that our profit is reinvested back into the business. For the last number of years, we’ve been building our own factory.

We believe, one of the best ways to improve, both ethically and environmentally, is by shortening our supply chain.

The more of the production process we control, the less that’s outsourced to third parties. That means, more oversight and the ability to ensure that every part of manufacturing - the labour conditions, the production process, and the materials, every thread, fabric, heel, lace – and their constituent parts, adhere to a similar value system. And that’s what traceability is all about.

The fashion industry has long been complicit in selling products that claim to be single origin, ‘Made in the UK’ or ‘Made in Italy’ but in fact, have a long supply chain that suggests something far more complicated. New regulations coming into effect in the EU in 2027, will mean that every product is required to provide a DPP (Digital Product Passport) a digital barcode that allows customers to see the provenance of a specific item’s component parts, giving more detail on the what, who and where the raw materials that go into making the product come from. This is progression. And we wholeheartedly agree with something that means more accountability at every stage of the making.

In fact, this month, we were featured in a Vogue Business article that asked the question, ‘Is it possible to build a fully traceable outfit?’ and “invited seven brands to tell the stories of their supply chain traceability journeys through a single garment.”

We told ours through a pair of Emile boots. 85% of the parts were traceable.

1. Insole

Cardboard

Raw material: Finland

Cardboard supplier: Portugal

Foam

Raw material: Spain

Foam supplier: Spain

Metal shank

Raw material: Spain

Metal shank supplier: Portugal

2. Heel

Inside of the heel

Raw plastic: South Korea

Material supplier: Italy

3. Top piece heel

Raw Thermoplastic

Polyurethane (TPU): Italy

Material supplier: Portugal

4. Back counter

Raw material (cotton): Italy

Back counter: Portugal

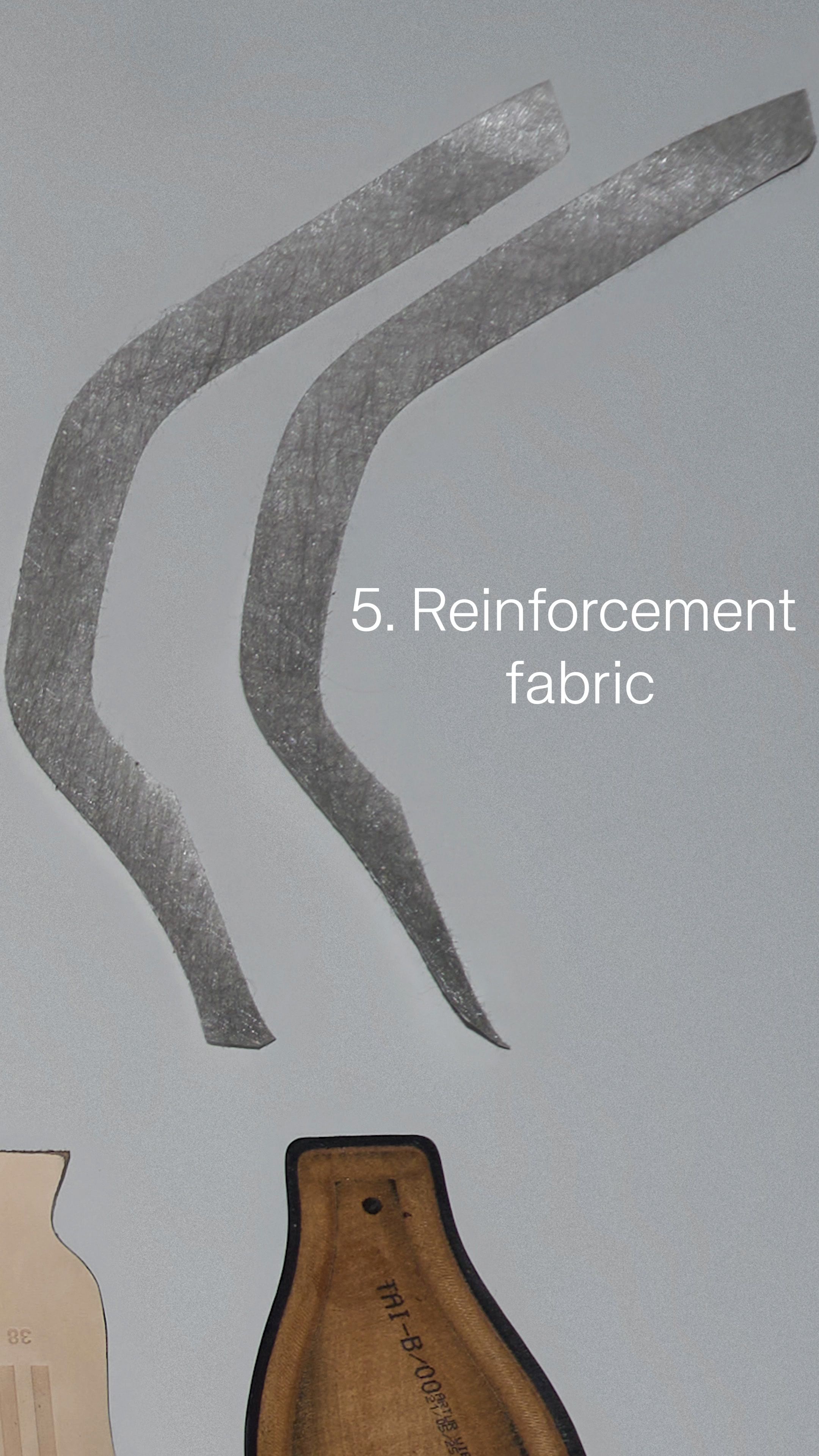

5. Reinforcement fabric

Raw material: China

Fabric supplier: Portugal

6. Metal eyelets

Raw material: Italy

Metal eyelet supplier: Portugal

7. Outsole

Leather: Nominated vendor in

Italy (80 per cent) / Nominated

vendor in Pakistan (20 per cent)

8. Leather laces

Raw material: Italy

Production: Miista / Portugal.

9. Zipper

Raw material: China

Zipper supplier: Portugal

10. Upper leather

Raw material: Italy

Leather supplier: Supplier Conceria 800

/ Pisa, Italy

11. Leather lining

Raw hide: Pakistan

Vegetable tanning: Spain

Lining supplier: Curtidos Manuel Sirvent

/ Alicante, Spain

But becoming completely traceable is no mean feat for any small, independent business.

Traceability doesn’t necessarily mean full transparency or sustainability.

It’s the same rules for us, as the big brands, and the fashion industry is built in favour of mass production and huge conglomerates, who often have more sophisticated systems and more people power. And yet, whilst the big guys can already show that they’re fully traceable, it doesn’t necessarily mean that they’re ethical or transparent.

Many do not own their own factory and it’s still all too common for their suppliers to sub-contract to other suppliers, further muddying the supply chain.

For us, we hope that governments will see the benefits of subsidising supply chain traceability for small companies. And also that the middlemen, the privately-owned agencies, who smaller companies have to go to source parts they cannot make themselves or order from source due to minimum amounts, things like non-EU raw materials that make up a zip, or the raw hide used for the leather lining in boots - are required to implement auditing and oversight to ensure the ethical and environmental credentials of the products. But we’ll see. In the meantime, we’ll continue to take control and be accountable for the products we do make.

SHORTENING THE SUPPLY CHAIN AND SHARING THE PROCESS AS WE GO.